5S: what do mean these letters more and more used by companies ?

5S is a method of work organized in 5 stages with the goal of significantly improving the order and cleanliness.

5S are particularly effective because they want to improve the housekeeping of your workshops and the rest of your premises in order to obtain the following advantages :

5S software is now available on request

The success of this kind of processes depends on a series of key factors.

Often, after a period of grace, bad habits resurface, and all the hard work done goes out of the window.

Factory Systems has practical experience and regular assignments in the field to enable you to embed the new techniques introduced by the 5S in new working practices.

The use of our 5S software, specifically designed for operators and supervisors, will guarantee that you have daily monitoring of the methodology and enable you to see any abnormalities and the progress made.

The 5S implemented by Factory Systems guarantee you concrete, lasting results.

The 5S method, which takes its name from the first letter of each of the five operations, is a Japanese management technique derived from the Toyota Production System (TPS). It is based on 5 simple principles:

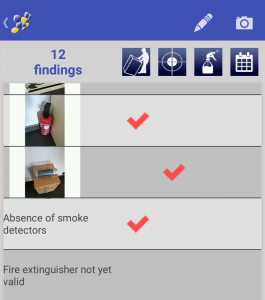

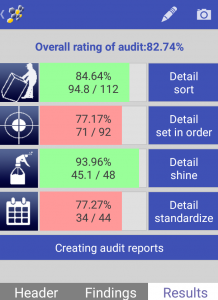

For optimal monitoring of your 5S, auditing is a critical phase that occurs early in the process (pre-audit), throughout the implementation to measure progress and final phase to validate results and certify the area.

Factory Systems has developed a simple and user-friendly 5S audit software specially designed to closely monitor the implementation of a 5S approach in your company. It will serve as an objective measurement tool from the initial situation to a 5S certification.

Based on real-life examples, it will be a valuable tool in your continuous improvement process.

Main features :